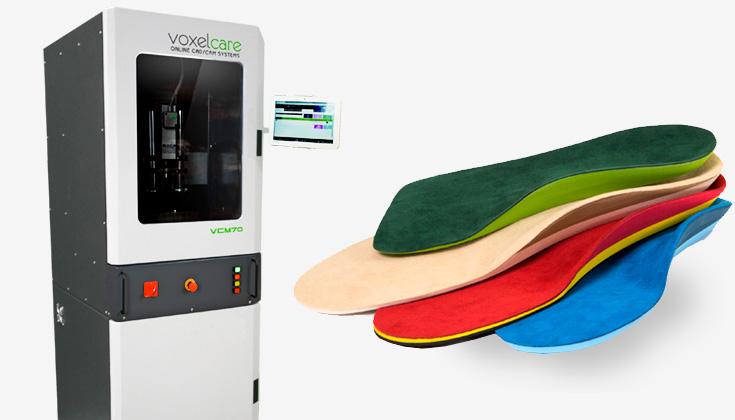

VCM70

Voxelcare Production

The VCM70 is a high-end 1 pair orthotic milling machine model where performance, reliability and accuracy is required. Ideal for milling for companies that want to (start) mill EVA orthotics in a clinical or shop environment.

Overview

High-end clinical technology

The VCM70 is a high-end 1 pair orthotic milling machine model where performance, reliability and accuracy is required. Ideal for milling for companies that want to (start) mill EVA orthotics in a clinical or shop environment.

User friendly operation

The VCM70 is designed so that any (beginning) user is able to quickly and easily start manufacturing custom insoles. After designing the orthotic in the online design program the design is automatically sent to the CAM which creates the milling files. After this put the EVA milling material in the machine and hit the green start button to start milling.

Powerful milling technology

Orthotics are 2-sided milled which will save a lot of manual finishing time and give a consistent quality product. Use different possible milling settings and mill your insoles with an accuracy of 0.01mm

Fully integrated solution

In the base unit a powerful dust extraction unit and vacuum pump (for holding the milling blocks) are integrated. The machine can be controlled from the supplied tablet as well as from a computer within the network. The machine is fully integrated within the Voxelcare online CAD/CAM system.

Advantages

2-Side milling

Mill insoles on 2-sides (top and bottom side), save a lot of time in manual grinding and finishing

Mill 1 pair

Suited for milling 1 pair of EVA orthotics

High Quality

Robust internal frame, incl. vacuum table, vacuum pump and dust extraction system

High performance engine

Brushless milling motor 1.1 Kw, 6000 – 24000 rpm

Time saving

Get you orthotics 99% finished out of the machine and save lot if time in manual finishing

Versatile and powerful

Transmissions in all axes of spindles, with screwball recirculating and stepping motors engines with encoder and 90 Kg/cm of torque per motor

Easy to use

Including tablet to control milling machine

Features

Dimensions

600 x 780 x 1750 mm

Working area

350 x 300 x 55 mm (Z axis height)

Weight

270 kg

Milling time

Up to 15 min/pair (two sides)

Accuracy

0.01 mm

Power

220V single phase

Required operating system

Windows 7 OS or a later version